Safer, More Efficient Cold Chain Management with RPA

(3 min read)

Cold chain logistics for temperature-sensitive goods are demanding and volatile. This is especially true in the pharmaceutical industry, where there is always a high risk that batches spoil on the way. During the SAP iRPA Hackathon we at NTT DATA Business Solutions Benelux created a use case to solve this critical challenge, that also provides a powerful blueprint for other industrial supply chains. And guess what? We won the contest.

Automating Safe Deliveries in Vaccine Distribution

All of us have experienced firsthand that COVID-19 requires decisive action. Security and speed are crucial in the global race against the pandemic. Once a vaccine is developed, it must be distributed quickly and safely – and in tremendous volumes. This poses an enormous challenge for supply chains, especially because the temperatures of the batches must always be kept between minus 18 and minus 70 degrees Celsius. Conventional data loggers – small devices that normally travel with the shipped batches of goods – should ensure safety. However, they have a significant disadvantage: they report problems very late. Namely, when the recipient reads the data AFTER the batch has arrived, i.e. when it is already spoiled. This challenge inspired our developers from NTT DATA Business Solutions Benelux (BNL) and me to create an innovative RPA use case for safe vaccine distribution.

An Award-Winning Cold-Chain Tracking Concept

For the solution prototype awarded at the SAP iRPA Hackathon, we combined SAP Intelligent Robotic Process Automation services with IoT technology by utilizing a real-life sensor tag. It constantly measures the temperature of batches and sends the data via Bluetooth to a smartphone. On the phone our NTT DATA Business Solutions IoT Sensor App receives the temperature data and forwards it to the SAP Cloud Platform, where additional information from the backend system is added. It then contains batch and product information, including temperature thresholds, and all relevant delivery information, such as the transport company and destination.

A small-footprint application based on SAP HANA XS checks the incoming sensor values against predefined thresholds – like the temperature limit. Once a threshold is exceeded, the app triggers one or more SAP Intelligent Robotic Process Automation bots, sending with it all the information required for specific actions, for example, batch numbers, or current location.

Different Thresholds, Different Bot Triggered Actions

During the design of the use case we defined two limits as thresholds. The warning limit triggers a text message (“Warning: Too warm! Cold chain may get interrupted!”), to inform the truck driver about a batch risk. Depending on the weather situation at the current location and on the route, the driver can then decide whether to take the load to the nearest cold store. In addition, the transport company is immediately informed of the problem by email.

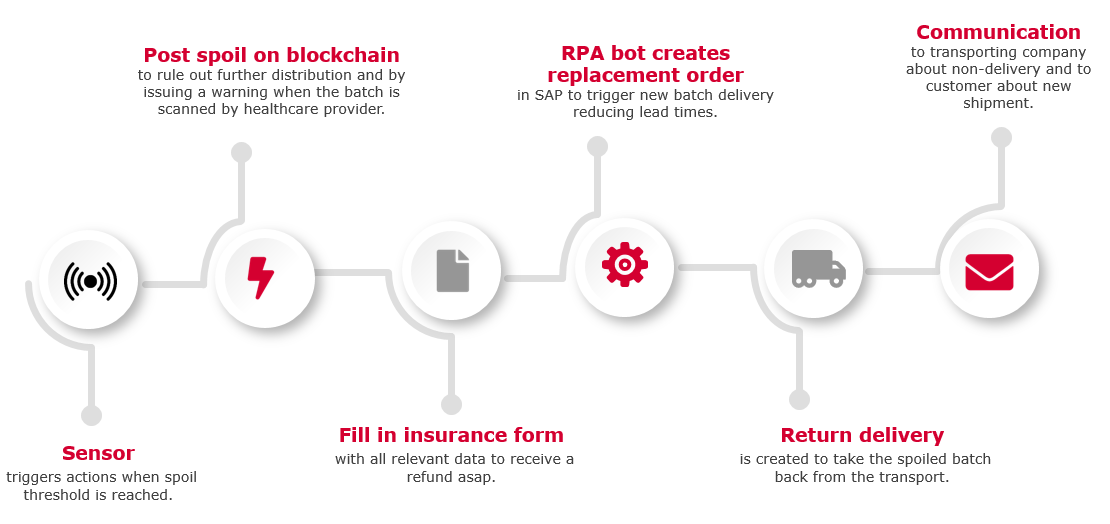

The second limit, the spoil limit, comes into play when the goods can no longer be saved. It triggers multiple bots for a broader set of actions, taking the batch out of the cold chain via blockchain. If desired, the system then immediately creates a replacement order – well before the goods would have been delivered to healthcare providers or patients. At the same time a returns order is created to return the spoiled goods to the supplier. Finally, the system automatically generates the necessary insurance documents and sends them to the insurance company.

A Powerful Blueprint for many Industrial Freight Scenarios

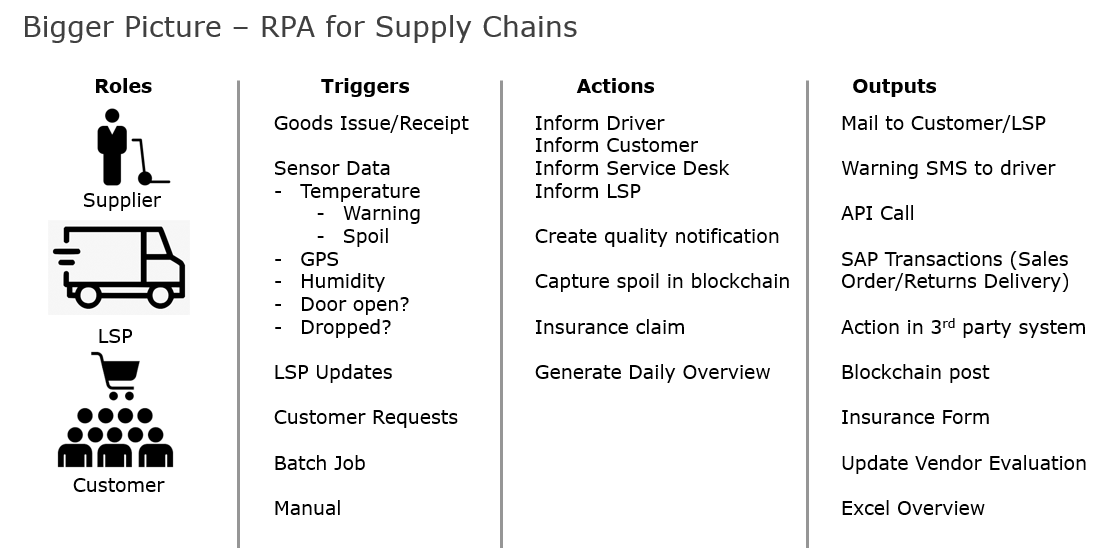

As this scenario shows, the smart combination of IoT devices and SAP Intelligent Robotic Process Automation bots can reduce a lot of repetitive and tedious work and provide considerably more security and efficiency to cold chain management. And not only within the cold chains of the life sciences or the food and beverage industries. Our solution concept is basically applicable to any freight scenario which requires constant control and monitoring of the transportation environment. Instead of a temperature sensor, we could use other sensors, e.g. sensors that indicate, if a box had been dropped, got wet or was opened. Each of these actions can trigger their own set of actions.

Based on this use case we can quickly develop further application scenarios for other industries that produce sensitive goods – from manufacturing and logistics to sales and maintenance. For each industry or customer and each product, NTT DATA Business Solutions will identify individual triggers, corresponding events, and actions. In addition to truck driver warnings, we can also integrate service and help desks. Furthermore, it is possible to automatically initiate new ordering and delivery processes or even insurance transactions: directly via the SAP system, by email or SMS. In other words: with RPA, the digital revolution in the logistics chain will quickly reach the next level of automation, efficiency, and security.

Learn more about life sciences